| |

|

Electrical Equipment |

|

|

|

Armstrong Chemtec

Group, having its parent company, Armstrong Engineering Associates,

Inc., in Pennsylvania in the U.S.A. and its wholly owned subsidiary, Chemtec UK

Ltd., in Beith in Scotland, is specializing in Process Heat Transfer.

For over 70 years,

Armstrong Chemtec Group has been designing and manufacturing heavy duty

industrial equipment for some of the most demanding and hazardous processes in

the Chemical, Petrochemical and Oil Refining Industries and has supplied the

same globally.

With design engineers who

are the most experienced and knowledgeable in the industry, Armstrong Chemtec

Group can determine the best type of electric heater for a specific application

and provide a perfect, custom designed heater for the desired process duty.

Armstrong Chemtec Group do

not size electric heaters from a table of watt densities, nor do they have a

standard line of light duty commercial heaters in sizes which never entirely

match the nonstandard requirements of their clients. Armstrong Chemtec Group’s

electric heaters are designed to meet all thermal and hydraulic constraints with

special attention given to the specific flow rates, pressure/temperature

conditions, fluid physical and corrosive properties and fouling potential for

each individual heater.

Armstrong Chemtec Group’s

electric heaters are uncompromisingly designed and manufactured to optimally

achieve each individual client's process, mechanical, safety and reliability

requirements.

The range of Armstrong Chemtec Group’s

Electrical Equipment is as follows; |

|

|

- Electrofin Immersion

Heaters - These finned element heaters are

especially suitable when process conditions or fluid properties result in a low

heat transfer rate from electric element to process fluid. The fins minimize

element temperature and thereby reduce the possibility of heating element

burnout and product degradation. These heaters have all the features of

Armstrong Chemtec Group's electric immersion heaters with the added advantage of

packing significantly more heat transfer surface into a smaller diameter shell.

Electrofin Immersion Heaters are used for heating low pressure gases, viscous

liquids and some two-phase mixtures of gases and liquids.

|

- Fluidized Bed and

Reactor Vessel Radiant Heaters - This type of radiant heater is used

for maintaining or increasing the temperature in a prescribed section of a

fluidized bed reactor or other reaction vessel. Such equipment is widely used in

the chemical process industries and often requires high temperature heating.

Armstrong Chemtec Group's radiant heaters have been widely used in such

installations where typical duties are for catalyst

regeneration/activation/dehydration or Polysilicon manufacturing. For this type

of application Armstrong Chemtec Group's radiant heaters are provided in three

120 degree sections so that they may be installed around the vessel and easily

removed for maintenance.Armstrong Chemtec Group's impedance heaters, ranging in

size from 10kW to larger than 1MW, have been used in a wide variety of difficult

process applications such as heating supercritical water & other fluids, high

temperature gas heating, tubular reactors requiring heat input, heating to

temperatures above 1850°F (1010°C) and heating fluids at pressure higher than

3500 psig ((240 barg.).

|

- Impedance Heaters

- Armstrong Chemtec Group's impedance heaters are direct electric heaters for

process fluids in which a metallic pipe transmits electric current and

simultaneously pressurizes fluid flowing along its length. The resistance of the

fluid carrying pipe produces heat which is absorbed by the fluid in contact with

the pipe’s inner surface. In this equipment, the pipe acts as the pressure

containment vessel, the heating element, and the heat transfer surface.

Armstrong Chemtec Group's design prohibits current from entering connecting

piping without special electrical isolation devices.

|

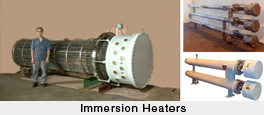

- Immersion Heaters

for heating process gases such as Hydrogen, Air, Hydrocarbons, Regeneration

Gases, Reduction Gases and others to temperature as high as 1112°F (600°C).

|

- Radiant Heaters

for heating fluids such as Hydrogen, Silicon Tetrachloride, Fluorine Compounds,

Hydrocarbons, Air, Helium and others.

|

- Control Panels

- Armstrong Chemtec Group custom designs and manufactures every power control

panel to assure that the specific heater, for which the controller was designed,

will provide the maximum performance. Every control panel is built to industrial

specifications, and all components used in the manufacture have been field

proven. Heavy duty and conservatively sized power cabling is used. Designs

according to NEMA, NEC, CSA and IEC are available where appropriate.

|

|

|

|

|

|

|

|

|

|